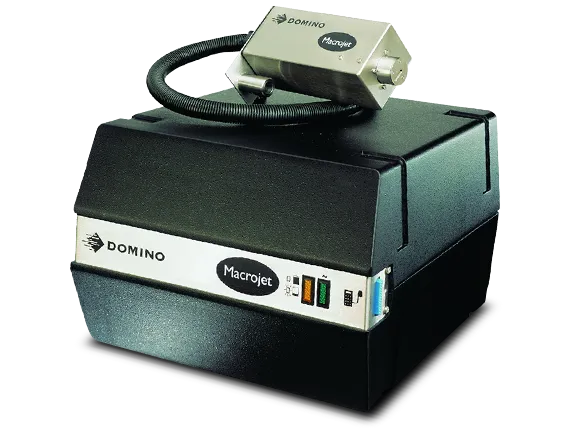

About Domino

Domino, founded in 1978, is a globally recognized leader in coding and printing technologies, known for setting new industry standards in quality and reliability. The company operates in over 120 countries, supported by 25 subsidiary offices and more than 200 distributors, employing over 2,700 people worldwide. Domino’s manufacturing facilities are located in the UK, China, Germany, India, Sweden, and the USA. Since June 11, 2015, Domino has been an autonomous division of Brother Industries Limited, a publicly traded company based in Nagoya, Japan.