About Integrated Systems

We are proud to offer a comprehensive suite of integrated systems designed to streamline, automate, and enhance your business operations at every level. Our advanced solutions seamlessly combine both physical and digital components, empowering your business with greater efficiency, control, and adaptability in today’s fast-evolving market.

Application Levels

Applications

Vision & Inspection Systems

We offer advanced precision and inspection systems to ensure top-tier quality control throughout production processes. Our solutions enhance accuracy and reliability, supporting the production of high-quality products. Our range includes systems for Print Message Inspection, Straw Inspection, OCV (Optical Character Verification), and OCR (Optical Character Recognition) on glass materials. Additionally, we provide specialized systems like the Tablets Inspection System, designed to ensure the quality of pharmaceutical tablets through thorough inspection.

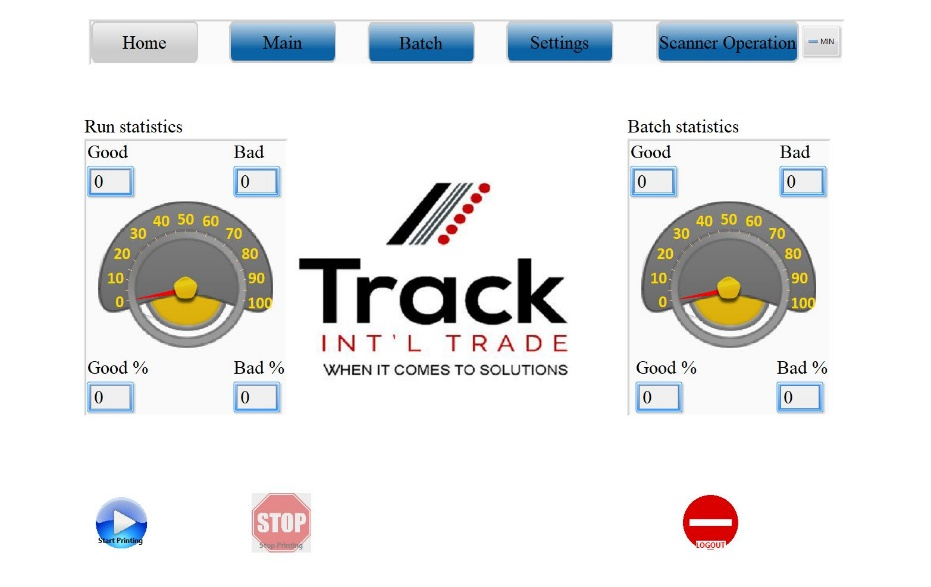

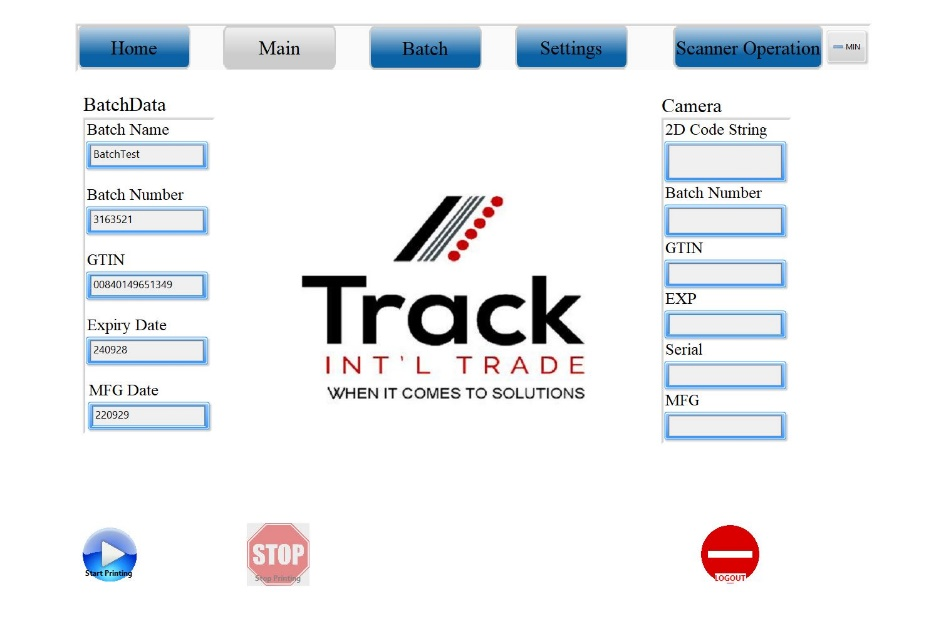

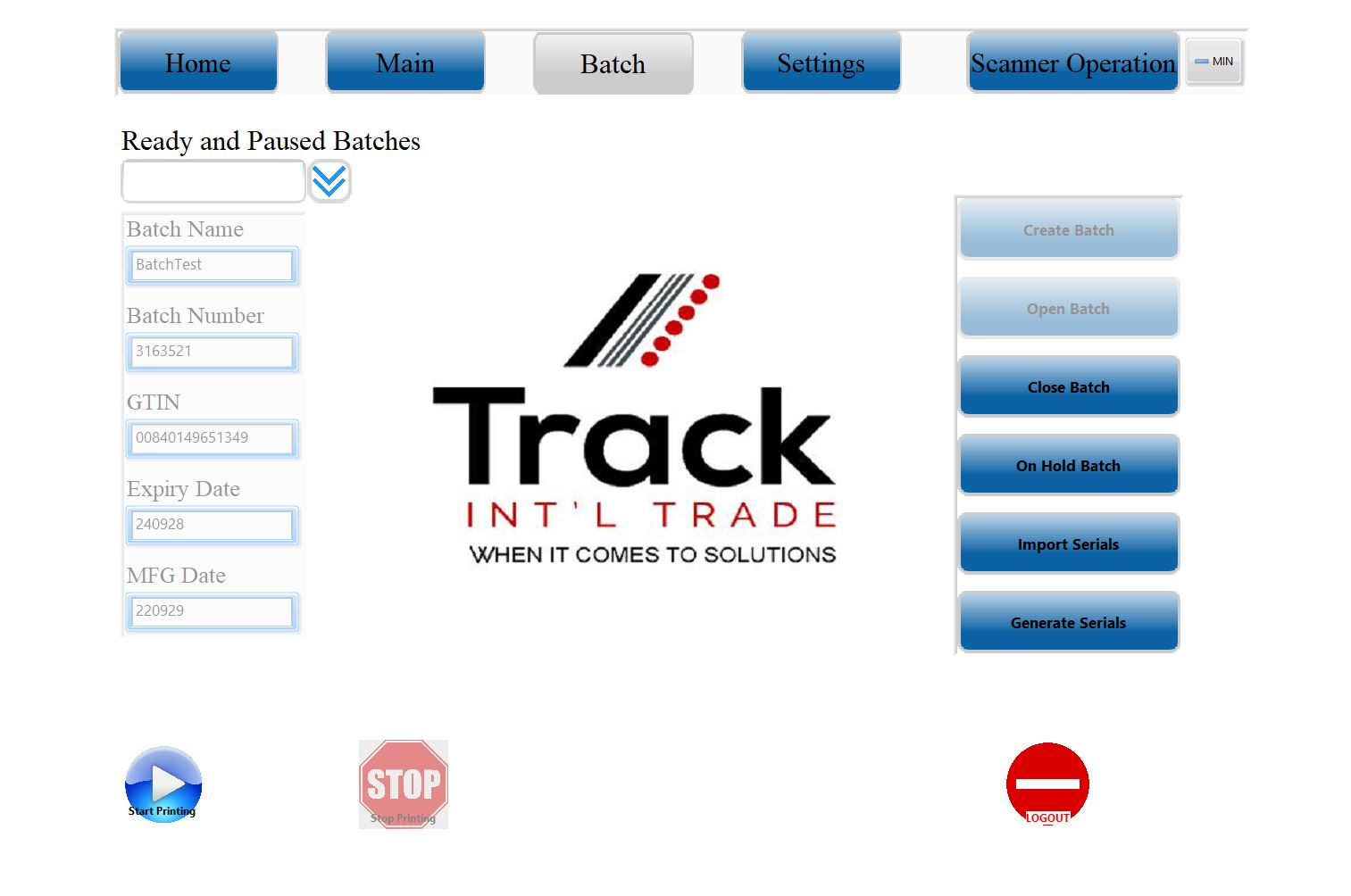

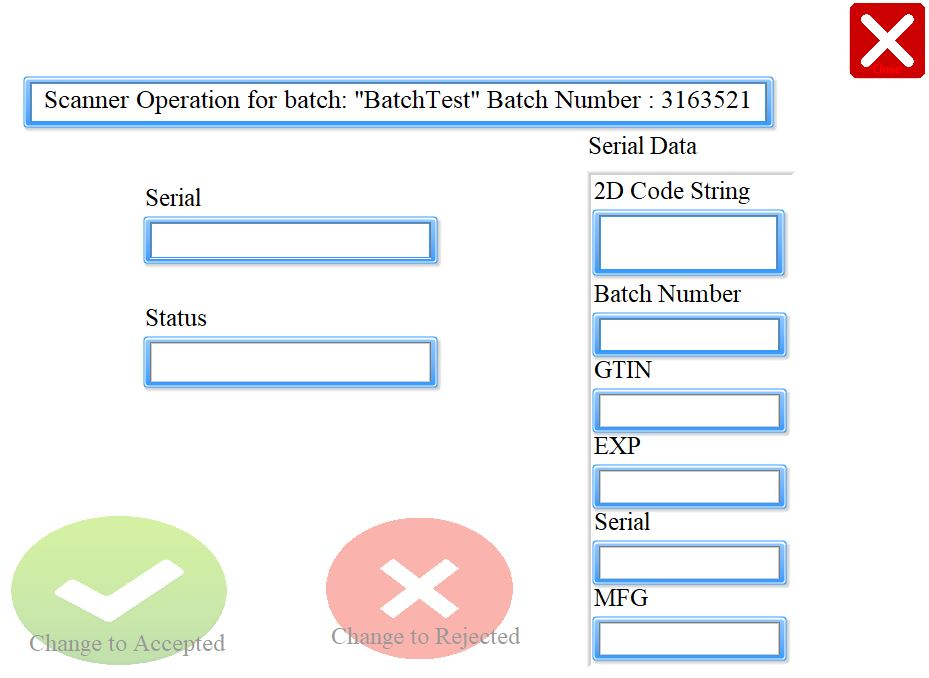

Track & Trace

We offer advanced Track & Trace systems that operate at the production level, managing and controlling batches through efficient serialization and aggregation processes. These systems ensure seamless tracking and traceability, while also reducing production errors, and improving overall efficiency across your production line.

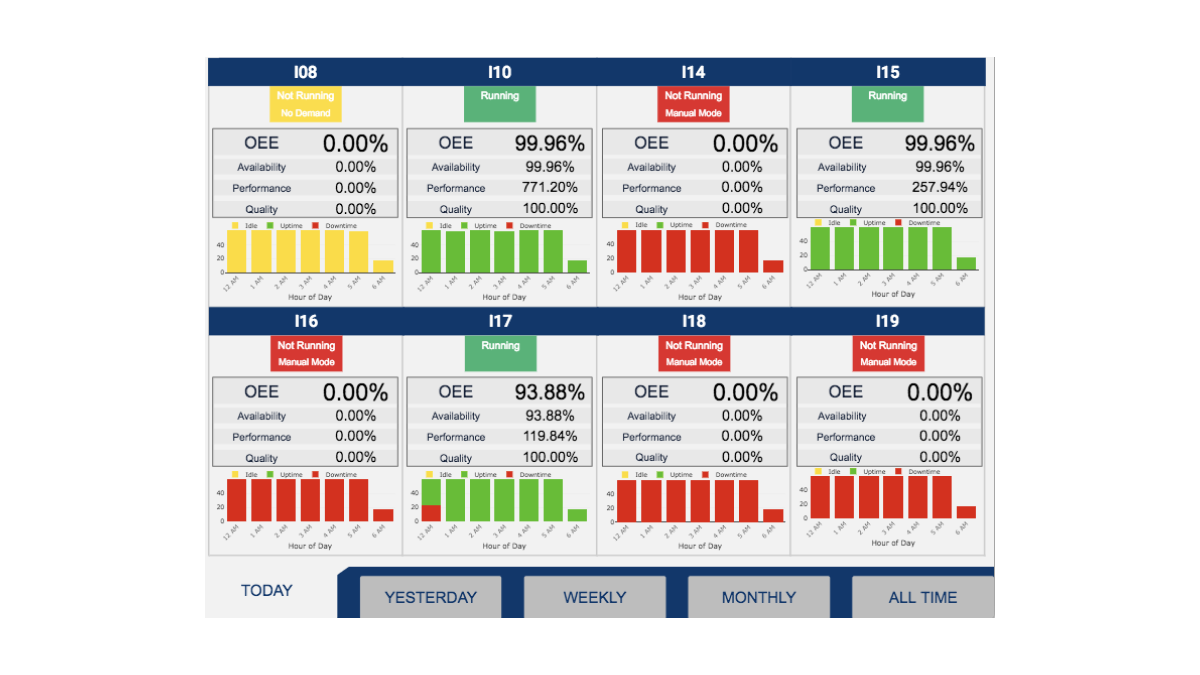

MES & OEE

We provide MES (Manufacturing Execution System) solutions that measure OEE (Overall Equipment Efficiency) for each production line. OEE is a key metric in evaluating the efficiency of your production processes, helping to optimize performance. By offering real-time insights, our MES empowers operations teams to make informed decisions and improve overall productivity.