Project Description

Twin IMT250 Series

Intermittent motion is a traditional and most used technology in the market today. Because of the simplicity, versatility and advanced packaging capabilities of the intermittent motion, it is the preferred option in many applications. IMT-250 Twinseries machines by using Servo-Motion Technology reaches the maximum speed that intermitted motion technology could achieve. The modular design of TWO-IN-ONE IMT-250 TwinMachine resulted in Ease of operation,Minimal maintenance,Quick changeover and setup, reduced operating cost, require one personnel, twice the production in same space as a single tube machine and the most attractive benefit is Ability of packing two different weighs at the same time.

Main Features

- Intermitted motion system

- Twin tube design (Two Outputs)

- Ability of packing two different weighs at the same time.

- Ease of operation

- Minimal maintenance

- Quick changeover and setup

- Reduced operating cost

- Mechanical Speeds up to 90 Bag/Minute per side.

- Twice the production in same space as a single tube

- Parts contact with product stainless ANSI 304 CR-NI steel

- Protection against corrosion

- SERVO-MOTION control system

- Auto-film centering.

- Easy adjustment and control with 12” industrial PC for Remote Access through internet (could be used in any preferred language)

- Work with or without Photocell, auto length measuring

- Precision and stable continuous horizontal and vertical heat sealing by P.I.D Control System

- Closed mechanic and electric systems

- Emergency stop system

- Failure warning system

- Automatic film roll holder shaft

- Easy load and splicing of the film

- Easy change over from one product to another

- Simple mechanic system

- Easy to setup and operate

- Adaptable for different filling systems such as; Volumetric weigher ,Linear weigher , Multi-head weigher , Auger filler , Piston filler etc.

- Bag material : Polipropilen , all laminated films, poliethilen

- Posibility for gusset device to make Square bottom bag ( for the future)

- Suitable for CE standarts

OPTIONAL FITTINGS/EQUIPMENTS

- Adaptable for different sealing systems such as; easy-open bag, euro-slot bag, round hole bag, straight cut, tear notch cut, and zig-zag cut.

- Vacuuming Supported Belts (extend belt life time and exceed speed of the machine up 15%)

- Gas Flushing System.

- Air conditioning on the control cabinet.

- 12” industrial PC man-machine interface.

- Static Eliminator.

- Printer.

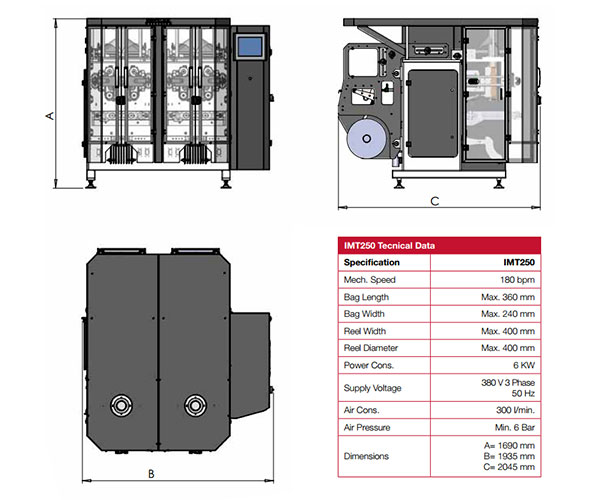

| Dimensions | |

|---|---|

| Width | 1935 mm |

| Length | 2045 mm |

| Height | 1690 mm |

| Weight | 1400 kg |

| Technical Data | |

| Mechanical Speed (Bag/min) | 180 |

| Operational Speed (Bag/min) | 140 |

| Bag length (Min. – Max.) | 40 – 350 mm |

| Bag width (Min. – Max.) | 30 – 240 mm |

| Reel Outer diameter | 400 mm |

| Reel Width | 500 mm |

| Power Requirement | 6 KW |

| Voltage requirement | 380 V 3 Phase 50 Hz |

| Hava gereksinimi | 150 lt/min. |

| Air pressure (Min.) | 6 Bar |